Optimizing Supply Chains with GIS

In today’s business world, making supply chains efficient is key to success. Geographic Information Systems (GIS) has changed how companies manage their logistics. GIS helps in optimizing supply chains, improving route planning, and making decisions based on data.

Using GIS in supply chain management gives companies a clear view of their operations. They can spot problems and make their processes smoother. GIS helps in planning routes and managing inventory, leading to better efficiency, lower costs, and happier customers.

Key Takeaways

- GIS technology offers a transformative approach to optimizing supply chain operations.

- Improved visibility, route planning, and data-driven decision-making are key benefits of implementing GIS in supply chains.

- GIS enables organizations to enhance efficiency, reduce costs, and improve customer service through logistics optimization.

- Integrating GIS into supply chain management can provide a competitive advantage in today’s fast-paced business environment.

- Leveraging the power of GIS can help supply chain professionals navigate the complexities of modern logistics and drive sustainable growth.

Introduction to GIS in Supply Chain Management

Geographic Information Systems (GIS) play a key role in today’s supply chain management. They combine spatial data analysis with logistics, helping businesses make smart choices. This section looks at what GIS is and why it matters in supply chain management.

Definition of GIS

GIS is a computer system that handles geographic data. It lets companies manage and analyze spatial information, like warehouse locations and routes. GIS gives a full view of the supply chain, helping with data-driven decisions and planning.

Importance of GIS in Supply Chain Management

GIS is now vital in supply chain management. It offers a strong platform for analyzing spatial data. This helps professionals in the field to better manage logistics, resources, and customer service. By using geographic data, businesses can spot chances, avoid risks, and make better strategic choices.

| Key Benefits of GIS in Supply Chain Management | Description |

|---|---|

| Optimized Routing and Transportation | GIS helps analyze transportation networks and routes. This leads to more efficient logistics and lower costs. |

| Inventory Management and Warehouse Optimization | GIS aids in managing inventory and finding the best warehouse locations. It improves warehouse operations for better efficiency. |

| Improved Customer Service | By using customer location data, GIS enhances customer service. It offers faster delivery and more personalized experiences. |

Using GIS in supply chain management is now crucial. It helps organizations optimize their operations, improve decision-making, and stay ahead in the market.

Benefits of Implementing GIS in Supply Chains

Using Geographic Information Systems (GIS) in supply chains brings many benefits. It makes logistics operations better and helps businesses grow. With GIS, companies can make smarter choices, work more efficiently, and save money.

Improved Decision-Making

GIS gives supply chain experts a clear view of their work. They can see data on maps and make better choices about stock, routes, and resources. This helps them solve problems early and find new ways to improve.

Enhanced Efficiency

GIS makes logistics run smoother. It uses real-time data to find the best routes and cut down delivery times. This makes customers happier and helps the business run better.

Cost Reduction

GIS helps companies save money in their supply chains. It finds ways to use less fuel and resources, which saves money. It also helps manage stock better and cut down on waste, saving even more.

| Benefit | Description | Impact |

|---|---|---|

| Improved Decision-Making | Comprehensive data visualization and analytics for strategic planning | Enhanced supply chain visibility and proactive problem-solving |

| Enhanced Efficiency | Optimized transportation routes, reduced delivery times, and improved responsiveness | Increased customer satisfaction and operational performance |

| Cost Reduction | Optimized resource utilization, reduced fuel consumption, and efficient inventory management | Significant savings in operational costs and increased profitability |

GIS is a game-changer for businesses. It helps them grow and serve customers better. The advantages of using GIS in supply chains are clear. It’s a must for companies wanting to succeed in the long run.

Key GIS Technologies for Supply Chain Management

In the fast-paced world of supply chain management, Geographic Information Systems (GIS) are making a big impact. They help businesses work smarter and faster. From advanced software to mobile apps, GIS offers many ways to improve supply chain operations.

Geographic Information Systems Software

GIS software is key for supply chain success. It combines spatial data, analytics, and visualization. This software lets managers plan, optimize, and track logistics with great accuracy.

It uses geospatial data to find the best routes and improve transportation networks. This helps make decisions based on up-to-date information.

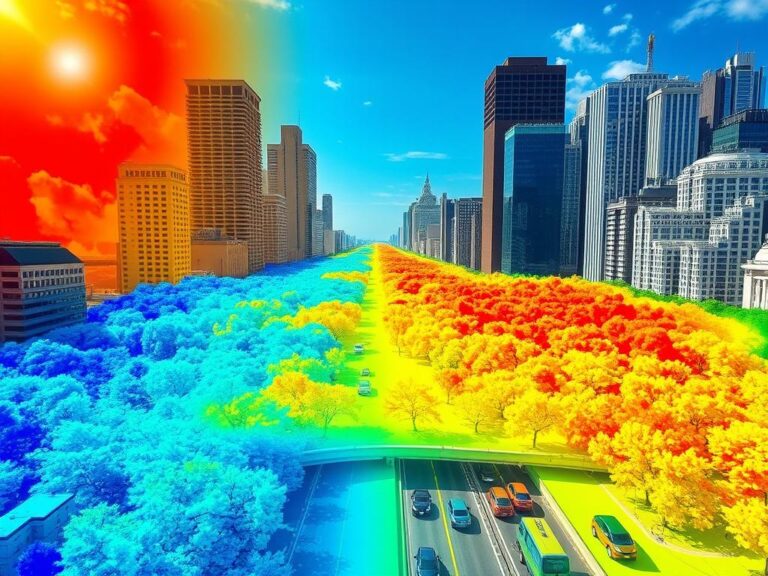

Data Visualization Tools

Data visualization tools are also crucial. They turn complex data into simple, clear visuals. These tools help spot trends and problems quickly.

They empower supply chain experts to make informed decisions. This leads to better efficiency and lower costs.

Mobile GIS Applications

Mobile GIS apps have changed the game for supply chain management. They allow for real-time data collection and decision-making on the go. These apps use GPS and mobile devices to give managers instant access to important info.

This lets them quickly adapt to market changes and customer needs. By using GIS technologies, supply chain teams can become more efficient, save money, and please customers more.

Role of Geographic Data in Supply Chains

In today’s world, geographic data is key to better supply chain operations. Geographic Information Systems (GIS) use spatial information to improve supply chain analytics. Knowing the different data sources and types is crucial for businesses to stay ahead.

Data Sources for GIS

Supply chain experts use many data sources for GIS. Some common ones are:

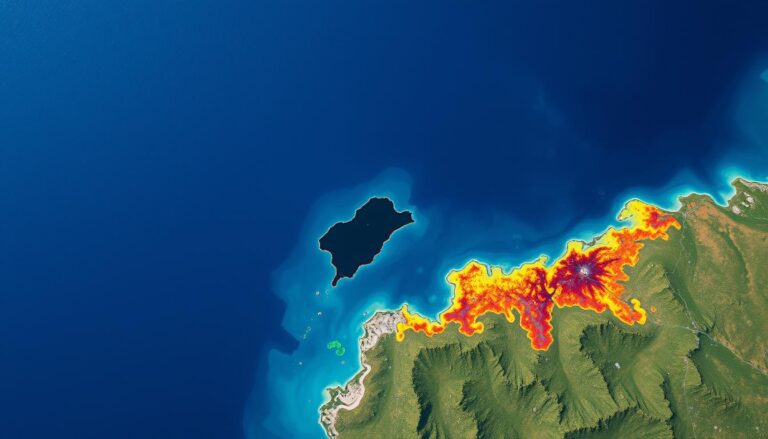

- Satellite imagery and remote sensing data

- Global Positioning System (GPS) coordinates

- Demographic and socioeconomic data

- Weather and climate information

- Infrastructure and transportation network data

Types of Geographic Data Used

Geographic data used in supply chain analytics is varied. Each type offers unique insights to improve supply chain visibility and performance. Some examples are:

- Geospatial data: Detailed maps, terrain information, and location-based attributes that provide a spatial context for supply chain operations.

- Logistics data: Information on transportation routes, distribution centers, and warehouse locations to optimize delivery and inventory management.

- Market data: Demographic and consumer trends data to identify optimal product placement and target customer segments.

- Environmental data: Weather patterns, natural disaster risks, and resource availability data to enhance supply chain resilience and sustainability.

By combining these different types of geographic data, supply chain managers can gain valuable insights. This helps improve decision-making and boosts operational efficiency in the entire supply chain.

Case Studies of GIS in Action

Real-world examples show how GIS changes supply chain management. It’s used in retail, transportation, and logistics. Companies use GIS case studies to improve their operations and stay ahead.

Retail Industry Examples

In the retail supply chain, GIS is very helpful. Big retailers use it to find the best store locations. They also analyze customer data and improve their distribution networks.

A big supermarket chain used GIS to pick the best places for new stores. They looked at population, traffic, and competitors.

Transportation and Logistics Success Stories

The transportation and logistics sector also benefits from GIS. Transportation logistics companies use it to plan the best delivery routes. This cuts down fuel use and costs.

One logistics company used GIS to better manage their fleet. They cut miles driven by 15% and lowered carbon emissions a lot.

| Industry | GIS Application | Key Benefit |

|---|---|---|

| Retail | Store location analysis | Optimized site selection |

| Transportation and Logistics | Route optimization | Reduced fuel consumption and costs |

These GIS case studies show how GIS changes supply chain management. Companies use spatial data and analytics to get better. They become more efficient, save money, and stay competitive.

Challenges in Integrating GIS into Supply Chains

Businesses aim to improve their supply chains by using Geographic Information Systems (GIS). However, they face big hurdles. Main problems include poor data quality and resistance to new technology.

Data Quality Issues

GIS needs good, accurate data to work well. But, many companies have trouble with this:

- Incomplete or wrong location data

- Different data formats and standards

- Old maps and information

- GIS not working with other systems

These problems can make GIS decisions less reliable. This can lead to poor supply chain plans and less efficient operations.

Technology Adoption Barriers

Getting GIS into supply chains also faces tech adoption hurdles:

- Employees not wanting to change

- Lack of GIS training

- Not enough GIS tools and support

- GIS not fitting with current systems

To beat these tech adoption barriers, a solid change plan is needed. This includes training, teamwork, and showing the benefits of GIS in supply chain management.

It’s key for businesses to tackle GIS integration challenges, data quality, and technology adoption to use GIS fully in supply chain management. By solving these issues, companies can make better decisions, work more efficiently, and save money.

How GIS Enhances Supply Chain Visibility

In today’s fast-paced business world, knowing what’s happening in your supply chain is key. Geographic Information System (GIS) technology helps a lot. It lets companies watch what’s happening in real-time and make smart choices based on data.

Real-Time Data Monitoring

GIS lets supply chain managers keep an eye on goods and resources as they move. It works with sensors and tracking tools to give a full view of the supply chain. This way, problems like delays or unexpected changes can be spotted and fixed fast.

Predictive Analytics

GIS also helps with predictive analytics. It looks at past data and patterns to predict future challenges. This could be weather issues, traffic jams, or changes in what customers want. Knowing this ahead of time lets companies plan better and stay flexible.

| Benefits of GIS-Enabled Supply Chain Visibility | Impact |

|---|---|

| Improved Decision-Making | Allows supply chain managers to make informed, data-driven decisions that optimize operations and mitigate risks. |

| Enhanced Efficiency | Enables real-time monitoring and predictive analytics, leading to improved resource allocation, inventory management, and transportation planning. |

| Increased Agility | Helps organizations quickly adapt to changing market conditions and unexpected events, improving their overall supply chain resilience. |

By using GIS technology, supply chain experts can see and react to things faster. This leads to better efficiency, lower costs, and happier customers.

The Future of GIS in Supply Chain Management

The world of supply chain management is changing fast. Geographic Information Systems (GIS) are at the forefront of these changes. They promise to change how businesses manage their logistics and operations.

Emerging Trends and Innovations

New advancements are making GIS even more powerful in supply chain management. Real-time data analytics are becoming key, helping managers make better decisions. Cloud-based GIS platforms are also making it easier for teams to work together and share data.

Potential Impact of AI on GIS

GIS and artificial intelligence (AI) together are set to change supply chain management. AI can automate tasks like routing and scheduling. It can also predict problems before they happen. This means GIS can help make supply chains more efficient and reliable.

As the supply chain world keeps evolving, using GIS technology will be key for businesses. By embracing GIS, companies can see and manage their supply chains better. This will help them stay ahead in the competitive world of supply chain management.

GIS and Sustainability in Supply Chains

Geographic Information Systems (GIS) are key to making supply chains more sustainable. They use spatial data to help companies cut down on carbon emissions and use resources better.

Reducing Carbon Footprint

GIS helps find and lower greenhouse gas sources. It improves how goods are moved by planning better routes. This cuts down on fuel use and emissions.

It also tracks the environmental effects of supply chain activities. This lets companies make choices based on data to reduce their carbon footprint.

Optimizing Resource Use

GIS is also important for using resources wisely in supply chains. It analyzes data to find ways to cut waste and improve how goods are stored and moved.

This leads to better use of things like energy, water, and raw materials. It makes the supply chain more sustainable.

| Metric | Before GIS Implementation | After GIS Implementation |

|---|---|---|

| Carbon Emissions | 15,000 metric tons CO2e | 12,500 metric tons CO2e |

| Resource Utilization | 78% efficiency | 85% efficiency |

Using GIS in supply chain management has shown big improvements. It has cut down carbon emissions and made better use of resources, as seen in the table. GIS gives companies the insights they need to make their operations more sustainable.

Best Practices for Implementing GIS in Supply Chains

Using GIS implementation best practices in supply chain management is key. It unlocks the full power of geographic information systems. A successful implementation needs a detailed plan that covers both technical and organizational sides. Let’s look at the main parts of this process.

Training and Development

Good supply chain training is vital. It makes sure everyone knows how to use GIS. This includes:

- Comprehensive training programs for GIS software and data management

- Hands-on workshops to help staff identify and leverage GIS insights

- Continuous learning opportunities to stay abreast of industry advancements

Aligning GIS with Business Goals

For business alignment, GIS must match the company’s logistics strategy and goals. This means:

- Doing a detailed check of the company’s supply chain and logistics needs

- Finding where GIS can make operations better and save costs

- Creating a clear plan to add GIS to current workflows and systems

By creating a GIS-friendly culture and aligning it with business goals, companies can use geographic data to improve their supply chains. This gives them a competitive edge.

| Best Practices | Description |

|---|---|

| Comprehensive Training | Provide extensive training programs for employees to understand GIS software, data management, and applications. |

| Hands-on Workshops | Organize practical workshops to help staff identify and leverage GIS insights for supply chain optimization. |

| Continuous Learning | Encourage ongoing learning opportunities to stay up-to-date with the latest GIS advancements and industry trends. |

| Business Alignment | Ensure GIS initiatives are closely aligned with the organization’s overall logistics strategy and strategic objectives. |

By following these GIS implementation best practices, companies can smoothly add GIS to their supply chain management. This leads to better decisions, more efficiency, and lower costs.

Conclusion: The Evolving Landscape of GIS in SCM

As we wrap up our look at Geographic Information Systems (GIS) in supply chain management, it’s clear GIS is key to the future of logistics. It has already brought big benefits, like better decision-making and cost savings. These changes have helped many businesses.

The future of GIS looks bright, with new trends like AI and predictive analytics on the horizon. These advancements will make GIS even more powerful. They will help supply chain experts tackle challenges before they start. Also, GIS will play a big role in making logistics more sustainable, helping to use resources better and cut down on carbon emissions.

As the world of supply chain management keeps changing, it’s more important than ever for businesses to use GIS. By using geographic data and tools, companies can stay ahead, work more efficiently, and succeed in the fast-paced world of logistics.